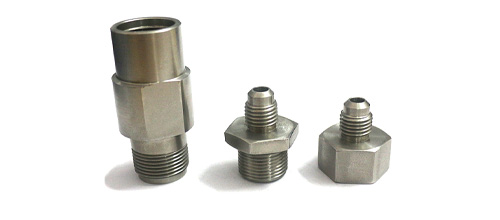

Precision Machining

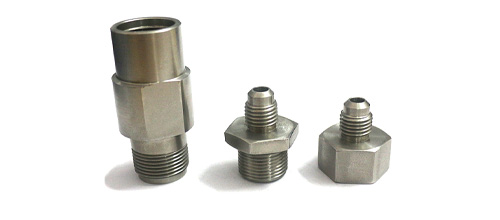

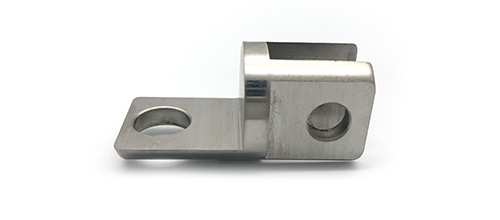

- CNC Machining Service

- CNC Milling

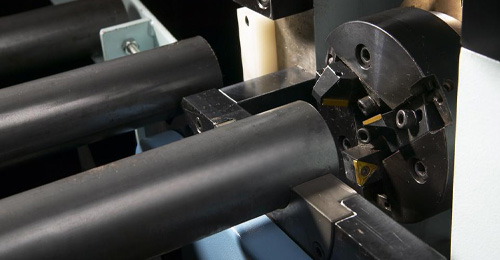

- CNC Turning

- Automatic Turning

- Machining Screw/Rivet

- Wire EDM Machining

- Casting & CNC

- Aluminum Profile & CNC

- Cold Heading & CNC

| Image | Material | Key Grades | Key Properties | Typical Applications | Processability |

|---|---|---|---|---|---|

| Polypropylene (PP) | Homopolymer, Copolymer, Glass-filled | Density: 0.89–0.91 g/cm³; Chemical resistance; Microwave-safe | Food containers, automotive parts, medical packaging | Melt temp: 200–300°C; Shrinkage: 1.5–2.5% |

| Polyethylene (PE) | HDPE, LDPE, UHMWPE | HDPE rigidity: 0.94–0.97 g/cm³; LDPE flexibility: 0.91–0.93 g/cm³ | Bottle caps, pipes, plastic bags, tubes | Melt temp: 180–280°C; Shrinkage: 2.0–4.0% |

| Polystyrene (PS) | GPPS, HIPS, EPS | ≥90% light transmittance; Rigid but brittle | Disposable cutlery, CD cases, instrument housings | Melt temp: 180–280°C; Shrinkage: 0.4–0.7% |

| ABS | Standard, Flame-retardant, High-impact | Impact strength: 20–40 kJ/m²; Glossy surface; Moderate weather resistance | Electronics housings, LEGO bricks, automotive interiors | Melt temp: 210–250°C; Shrinkage: 0.5–0.7% |

| Polyamide (Nylon) | PA6, PA66, PA11, Glass-filled | Tensile strength: 80 MPa; Self-lubricating; Hygroscopic | Gears, bearings, sports equipment | Pre-drying required (80–120°C); Melt temp: 260–290°C |

| Polycarbonate (PC) | Standard, Optical, Flame-retardant | Impact resistance: >60 kJ/m²; 90% transparency; HDT 130–140°C | Bulletproof glass, helmets, medical devices | Melt temp: 280–320°C; Prone to stress cracking |

| POM | Homopolymer, Copolymer, PTFE-lubricated | Flex modulus: 2.5–3.5 GPa; Low friction (μ=0.15–0.25) | Precision gears, bearings, zipper teeth | Melt temp: 190–210°C; Mold temp: 80–120°C |

| PMMA | Cast, Extruded, Impact-modified | 92% light transmittance; UV-resistant; High surface hardness | Lenses, signage lightboxes, automotive taillights | Melt temp: 240–260°C; Scratch-prone |

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

There is no necessary to have aesthetic look.Machining veins will be seen

slogan:Removes surface streaks and defects, make surface matt and rough

There is no necessary to have aesthetic look.Machining veins will be seen

You are guaranteed 30% lower costs and competitive prices to help you settle your material and start your project.

Apart from self-owned factory, we have thousands of suppliers to maintain a stable supply of materials.

Each of our material bears certified material certification to guarantee excellent quality for your parts.

Creative engineers and technicians are happy to help and recommend the suitable material for you.

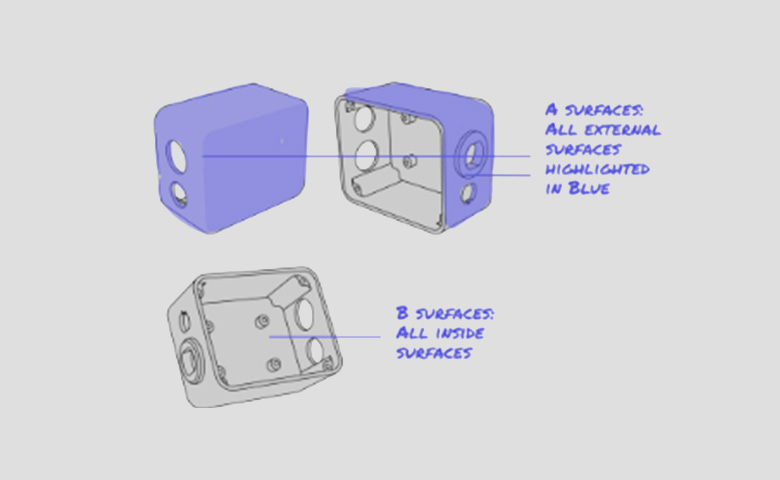

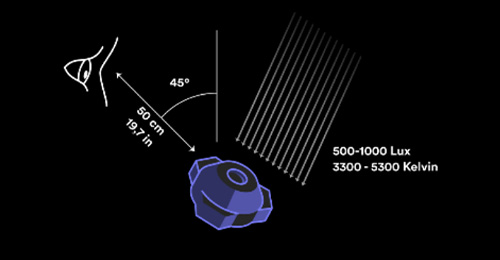

Surface finishing often leaves aesthetic defects on yourparts, such as hang marks for anodizing. Defining an Aand a B-side in your design will ensure that the most important areas of your part remain free of defects

In this image you can see how you can define an A-side and a B-side in your technical drawina:

A side: Indicates the most aesthetically importantsurface, typically the visible side of your product.

B side: Indicates the side that is not aesthetically important, typically the side hidden from visibility after assembly

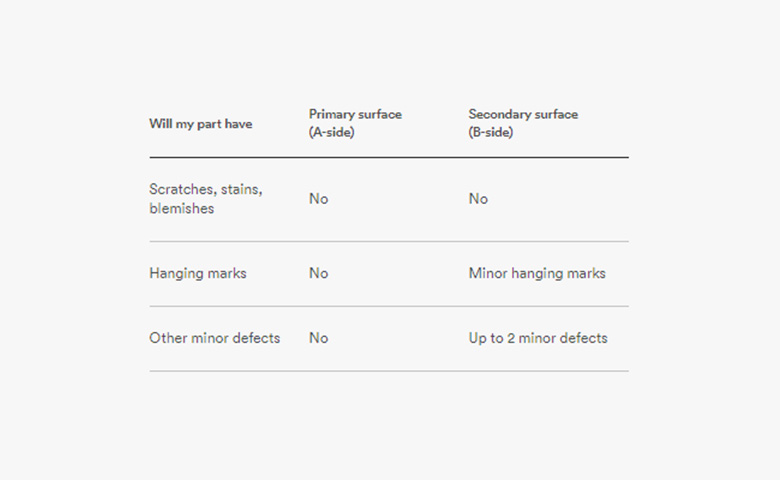

For the primary surface (A-side) of your part, we guaranteedefect-free production. In contrast, secondary surfaces (B-side)may be machined with hanging marks and other minor defects. Bside surfaces, like the rest of your part, will be free of scratches.stains and blemishes.

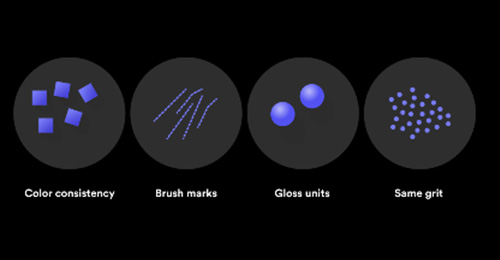

Each part must be visually consistent across the same batch.meaning:

* Manual brushing marks will be as unidirectional aspossible. Please note that for rounded geometries, brushingmarks may not be entirely unidirectional.*

The surface quality of every part must meet the followingconditions: