Precision Machining

- CNC Machining Service

- CNC Milling

- CNC Turning

- Automatic Turning

- Machining Screw/Rivet

- Wire EDM Machining

- Casting & CNC

- Aluminum Profile & CNC

- Cold Heading & CNC

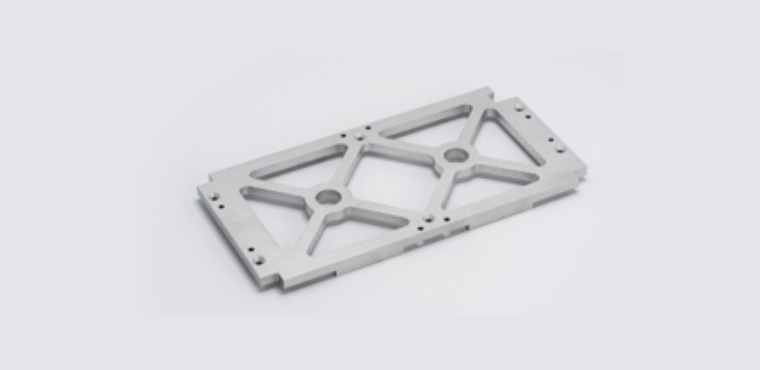

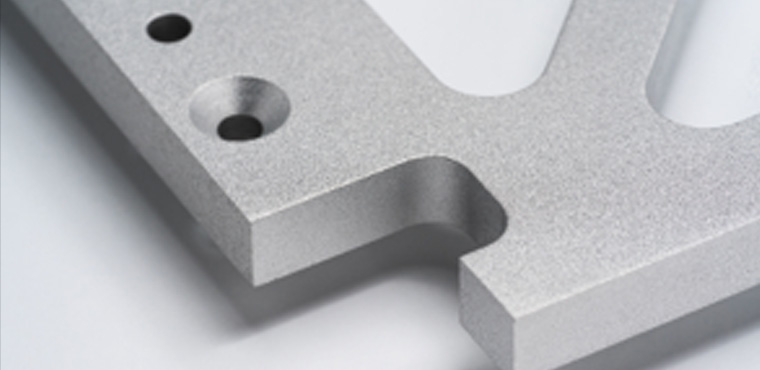

Smooth Machining delivers clean, defect-free metal surfaces by removing burrs, sharp edges, and irregularities from machined parts. This essential finishing process achieves a uniformly smooth texture while maintaining critical dimensions, improving both functionality and visual quality.

We customize surface finishes based on client specifications and functional needs. While options range from protective coatings and complex textures to specialized polishing, Smooth Machining serves as our essential baseline process, ensuring every part leaves our facility clean and functional.

Our standard Smooth Machining delivers burr-free surfaces with controlled roughness (typically Ra ≤ 1.6 μm), eliminating sharp edges and tool marks. This satisfies critical functional requirements including precision assembly fit (shafts, housings), reliable sliding contact, fluid sealing integrity, and visual cleanliness for industrial machinery, automotive components, jigs, and functional prototypes. It guarantees safety and reliability when complex coatings aren’t needed.

Ra values (e.g., 0.4μm for fine finishes, 3.2μm for industrial grades) efficiently specify general-purpose smoothness for non-critical fits or aesthetic parts. Rz better predicts functional performance where peak irregularities matter – such as bearing contact, fluid sealing surfaces, or coating adhesion. Choosing between Ra and Rz depends on functional needs: Ra for consistent texture control, Rz for critical interfaces. Additional parameters like Rmax (single worst-case peak-to-valley) or Rq (RMS average) address niche requirements, but Ra and Rz remain the essential benchmarks for industrial specifications.

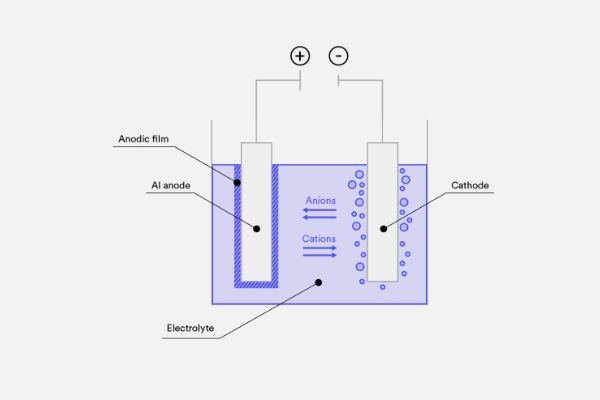

The sulfuric acid process is the most common method for anodizing. The sulfuric acid anodize process films range from .0001"-.001" thick. The overall thickness of the coating formed is 67 percent penetration in the substrate and 33 percent growth over the original dimension of the part. It is particularly suited for applications where hardness and resistance to abrasion is required.

The porous aluminum oxide absorbs dyes well, and subsequent sealing helps to prevent color loss in service. Although dyed anodized films are reasonably colorfast, they have a tendency to bleach under prolonged direct sunlight.

Some of the colors are: Black, Red, Blue, Green, Urban Grey, Coyote Brown, and Gold. Parts can be treated chemically or mechanically prior to anodizing to achieve a matte (non-reflective) finish.

Hardcoat anodize, while usually done in a sulfuric acid based electrolyte, is much thicker and denser than the more conventional sulfuric anodize. Hardcoat is specified for aluminum components subject to extreme wear applications where superior abrasion resistance is needed, or corrosive environments where a thicker, harder, more durable coating is necessary.

It can also be valuable where enhanced electrical insulation is required. Since hardcoat anodize can be built up to several thousandths in some cases, it makes this type of anodize a candidate for salvaging worn or mis-machined components.

Similar to: RAL 9004, Pantone Black 6

Similar to: depends on material

Similar to: RAL 3031, Pantone 1805

Similar to: RAL 5015, Pantone 3015

Similar to: RAL 1037, Pantone 715

Similar to: RAL 1012, Pantone 612

| Type | Impracticable situation | Features | Thickness(μm) | Application | Colors | PIC |

|---|---|---|---|---|---|---|

| Chromic acid (Type |) | a.Aluminum alloy parts with copper content > 5% b.Aluminum alloy parts with copper and silicon content > 7.5% | maintains the accuracy and surface roughness of original parts ,well bonding preformance | 3μm | a.1. Lap, riveted, welded or complex shaped parts b. Parts with high precision and low roughness | black,other color is imparctical |  |

| Sulfuric acid (Type II ) | Lap, spot weld or riveted part | the most common type of anodizing,can dye with a greater variety of colors | 0.5~20μm | The part that need brighten appearance or special color, as decoration or identification mark. | Black, Red, Blue, Green, Coyote Brown, Urban Grey, and Gold,allow for practically any hue |  |

| Hard Anodize (Type 1I) | Parts with high fatigue performance requirements | superior abrasion performance and electrical insulation,HV>420 | 30~120um | valves/hinges/cams/gear/insulation plates | black,other colors are less ornamental |  |

| Organic acid (Type IC) | uneven and amorphous black regions develop. | Anodizing can produce yellowish integral colours without dyes if it is carried out in weak acids with high voltages, high current densities, and strong refrigeration. | upto50um | Integral colour anodizing | pale yellow, gold, deep bronze, brown, grey, and black |  |

Take advantage of our network and see what LML can do for you