Precision Machining

- CNC Machining Service

- CNC Milling

- CNC Turning

- Automatic Turning

- Machining Screw/Rivet

- Wire EDM Machining

- Casting & CNC

- Aluminum Profile & CNC

- Cold Heading & CNC

Every penny is deserved

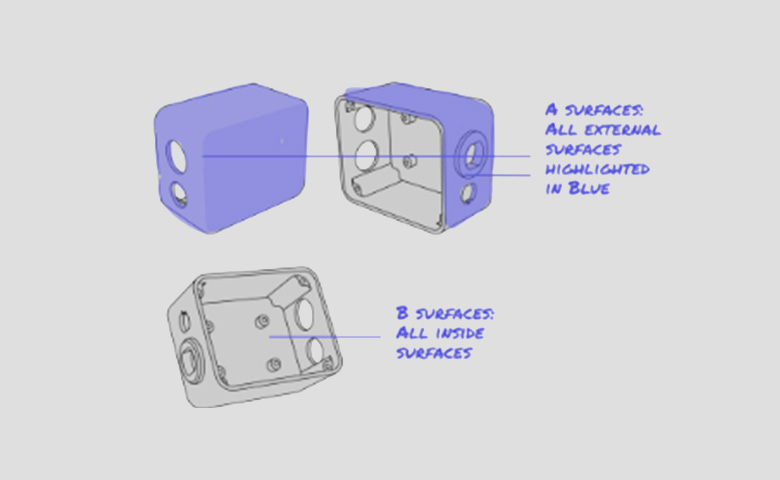

Surface finishing often leaves aesthetic defects on yourparts, such as hang marks for anodizing. Defining an Aand a B-side in your design will ensure that the most important areas of your part remain free of defects

In this image you can see how you can define an A-side and a B-side in your technical drawina:

A side: Indicates the most aesthetically importantsurface, typically the visible side of your product.

B side: Indicates the side that is not aesthetically important, typically the side hidden from visibility after assembly

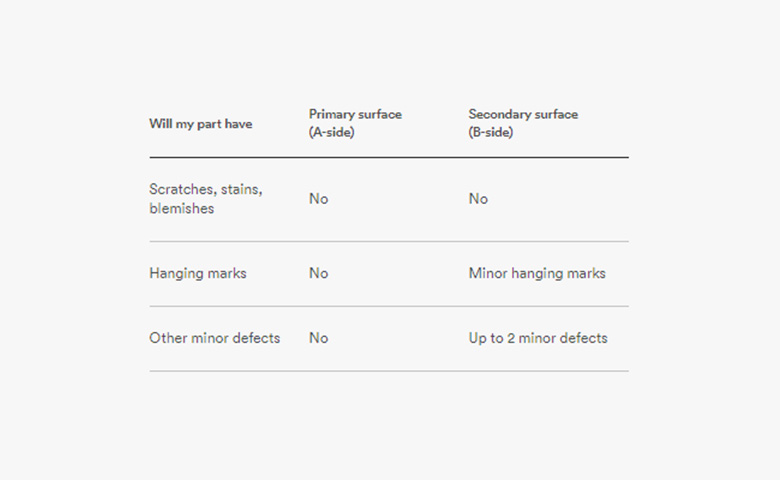

For the primary surface (A-side) of your part, we guaranteedefect-free production. In contrast, secondary surfaces (B-side)may be machined with hanging marks and other minor defects. Bside surfaces, like the rest of your part, will be free of scratches.stains and blemishes.

On December 12 , 2019,LML welcomed three customers again.

Read more about quality assurance

On December 12 , 2019,LML welcomed three customers again.

Read more about quality assurance

On December 12 , 2019,LML welcomed three customers again.

Read more about quality assuranceTake advantage of our network and see what LML can do for you