Precision Machining

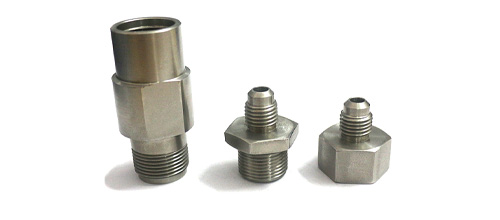

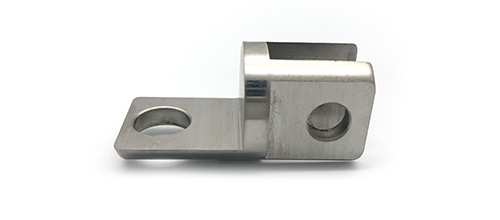

- CNC Machining Service

- CNC Milling

- CNC Turning

- Automatic Turning

- Machining Screw/Rivet

- Wire EDM Machining

- Casting & CNC

- Aluminum Profile & CNC

- Cold Heading & CNC

| Image | Material | Key Grades | Key Properties | Typical Applications | Processability |

|---|---|---|---|---|---|

| ABS | PA-757, PA-777 | High impact resistance, surface hardness | Appliance housings, auto dashboards | Good: Easy injection/extrusion |

| FR4/G10 | FR4 (epoxy + glass) | High strength, insulation, heat resistant | PCB substrates, aerospace parts | Poor: Lamination only |

| Nylon (PA) | PA6, PA66, PA12 | Wear resistance, self-lubricating | Gears, bearings, sportswear | Moderate: Drying required |

| PEEK | PEEK-1000, PEEK-CF30 | Heat resistant (240°C), chemical resistance | Aerospace, medical implants | Difficult: High-temp molding |

| PET | PETG, APET | Transparency, chemical resistance | Bottles, packaging films | Moderate: Fast cooling needed |

| PMMA (Acrylic) | PMMA 8N, VH001 | 92% light transmission, surface hardness | Lenses, taillights, displays | Moderate: Bubble prevention |

| POM (Delrin) | POM-H, POM-C | Rigidity, low friction, dimensional stability | Gears, bearings, zippers | Good: High flowability |

| PTFE (Teflon) | PTFE 7A, TF1625 | Lowest friction (0.04), chemical resistance | Seals, non-stick coatings | Very Difficult: Sintering only |

| PVC | PVC-U, PVC-P | Flame retardant, low cost | Pipes, wire conduits | Good: Easy extrusion/injection |

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

There is no necessary to have aesthetic look.Machining veins will be seen

slogan:Removes surface streaks and defects, make surface matt and rough

There is no necessary to have aesthetic look.Machining veins will be seen

You are guaranteed 30% lower costs and competitive prices to help you settle your material and start your project.

Apart from self-owned factory, we have thousands of suppliers to maintain a stable supply of materials.

Each of our material bears certified material certification to guarantee excellent quality for your parts.

Creative engineers and technicians are happy to help and recommend the suitable material for you.

LML provides advanced CNC plastic machining services, delivering superior product quality and fast turnaround. We operate over 40 CNC machining centers and lathes dedicated to plastics processing, offering both capacity and competitive pricing. We specialize in prototyping and small-batch production with a MOQ of 1, handle complex geometries, and accommodate urgent orders. At LML, you’re not just a client—you’re a collaborator, and we’re your trusted manufacturing partner in China.

Plastic machining is the subtractive process of shaping a solid plastic workpiece into a finished part using computer-controlled equipment. CNC (Computer Numerical Control) machining enables precise, repeatable production of complex 3D geometries designed in CAD (Computer-Aided Design) software. Our workshop is equipped with 3- and 5-axis CNC machines capable of handling a wide range of engineering plastics—from POM and nylon to high-performance PEEK and PEI—while maintaining tight tolerances and excellent surface finishes. Every part undergoes thorough DFM (Design for Manufacturability) analysis to ensure optimal manufacturability and cost-effectiveness.

CNC milling for plastics involves rotating multi-point cutting tools to remove material from a stationary workpiece, creating features such as pockets, slots, contours, and complex 3D surfaces. Our 3-axis and 5-axis milling centers allow for high-precision machining of plastic parts with tight tolerances up to ±0.05 mm (±0.002 in). The use of sharp, polished cutters, optimized coolant strategies, and controlled machining parameters ensures minimal heat buildup, reduces internal stress, and prevents material deformation—critical for achieving dimensional stability in plastic components.

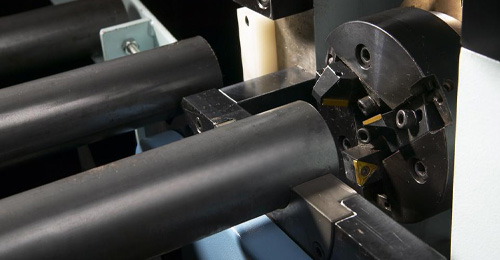

CNC turning of plastics uses a stationary cutting tool to remove material from a rotating cylindrical workpiece, ideal for producing round, concentric, or axi-symmetric parts such as bushings, rollers, and enclosures. Our CNC lathes and turning centers are configured for plastics, with adjustable spindle speeds, fine feed controls, and specialized tooling to prevent melting, chattering, or burr formation. This process delivers excellent concentricity, smooth finishes, and high repeatability, making it perfect for high-volume runs of precision plastic turned parts.

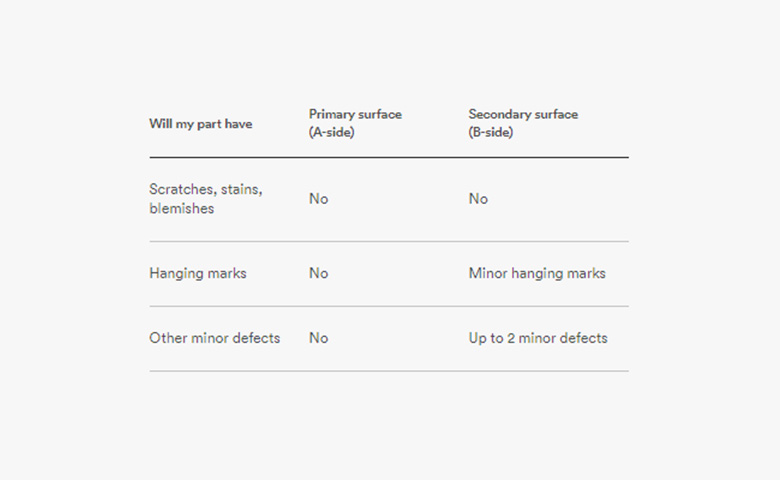

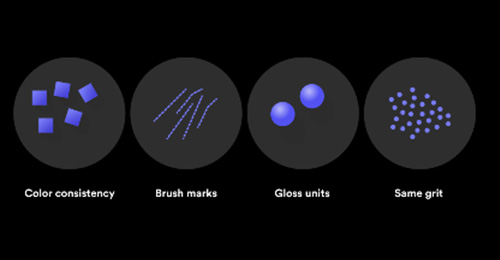

Each part must be visually consistent across the same batch.meaning:

* Manual brushing marks will be as unidirectional aspossible. Please note that for rounded geometries, brushingmarks may not be entirely unidirectional.*

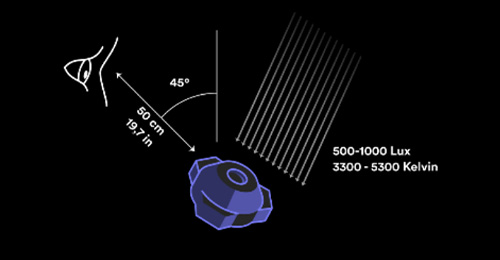

The surface quality of every part must meet the followingconditions:

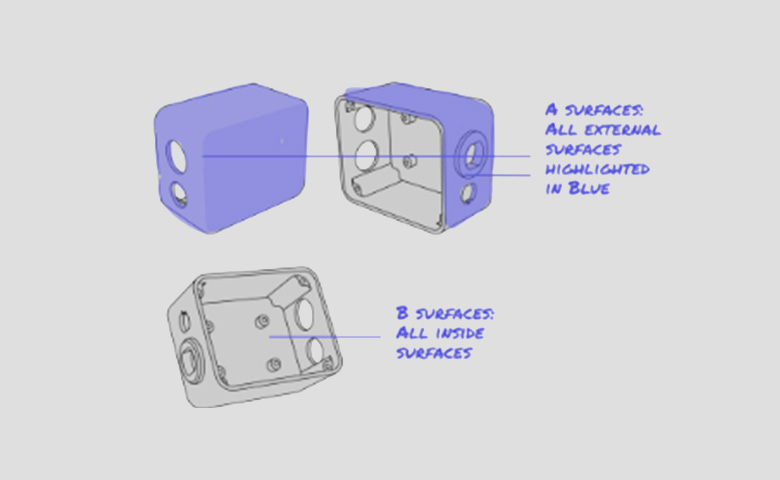

Surface finishing often leaves aesthetic defects on yourparts, such as hang marks for anodizing. Defining an Aand a B-side in your design will ensure that the most important areas of your part remain free of defects

In this image you can see how you can define an A-side and a B-side in your technical drawina:

A side: Indicates the most aesthetically importantsurface, typically the visible side of your product.

B side: Indicates the side that is not aesthetically important, typically the side hidden from visibility after assembly

For the primary surface (A-side) of your part, we guaranteedefect-free production. In contrast, secondary surfaces (B-side)may be machined with hanging marks and other minor defects. Bside surfaces, like the rest of your part, will be free of scratches.stains and blemishes.