Precision Machining

- CNC Machining Service

- CNC Milling

- CNC Turning

- Automatic Turning

- Machining Screw/Rivet

- Wire EDM Machining

- Casting & CNC

- Aluminum Profile & CNC

- Cold Heading & CNC

Your trusted resource for mastering the manufacturing technologies that bring your ideas to life. These comprehensive guides, built on years of hands-on experience, provide the practical insights you need to design for quality, efficiency, and cost-effectiveness with confidence.

Your guide to the basics: learn how to use milling, turning, and multi-axis machines to craft accurate custom parts.

Your guide to the basics: explore how to turn digital models into physical parts using popular technologies like FDM, SLA, and SLS.

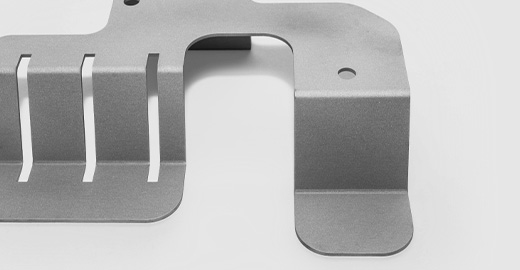

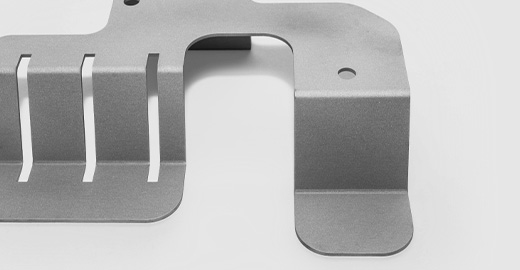

Your guide to the basics: learn key processes like cutting, bending, and assembling to create durable metal structures and enclosures.

Select the ideal finish to enhance the appearance, durability, and function of your parts.

Discover how to achieve vibrant and durable colors on aluminum parts through the anodizing process.

By leveraging the strengths of CNC machining and casting, LML optimizes production efficiency while maintaining exceptional quality standards.

On December 12 , 2019,LML welcomed three customers again.

Read more about quality assurance

On December 12 , 2019,LML welcomed three customers again.

Read more about quality assurance

On December 12 , 2019,LML welcomed three customers again.

Read more about quality assuranceTake advantage of our network and see what LML can do for you