Precision Machining

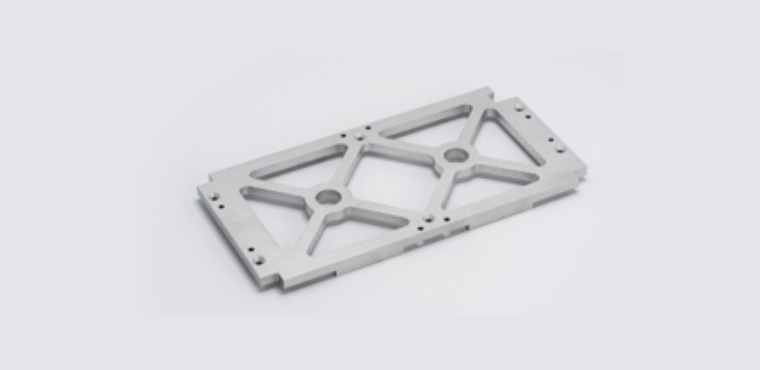

- CNC Machining Service

- CNC Milling

- CNC Turning

- Automatic Turning

- Machining Screw/Rivet

- Wire EDM Machining

- Casting & CNC

- Aluminum Profile & CNC

- Cold Heading & CNC

The stainless steel polished service is a multi-stage process that gradually refines the metal's surface using progressively finer abrasives to achieve a smooth, mirror-like finish.

Mirror polishing aims to create an exceptionally smooth, reflective surface with a high-gloss, mirror-like appearance that clearly reflects images. It is achieved by progressively refining the surface to eliminate all visible scratches and imperfections.

The finish is characterized by its high reflectivity and brilliant luster. The final surface is non-porous, which enhances corrosion resistance and makes it easy to clean. The process requires significant skill and progressive steps to achieve a defect-free mirror effect.

The classic finish is a clear, bright silver (the natural metal color). For decorative purposes, a mirror-polished surface can serve as an excellent base for subsequent Physical Vapor Deposition (PVD) coating, allowing for colors like Gold, Rose Gold, Black, and Blue while retaining high reflectivity.

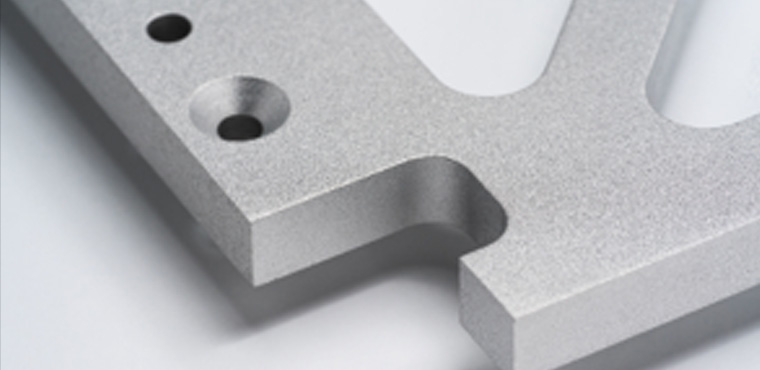

Matte polishing creates a uniform, low-gloss surface that diffuses light, minimizing reflections and glare. It focuses on achieving a specific, consistent texture rather than high reflectivity.

This finish is defined by its controlled, non-reflective texture. Common types include:

1. Brushed: Features fine, parallel or circular abrasive lines.

2.Satin: A finer, more uniform version of brushed, with a softer feel.

3.Bead Blasted: A matte, finely textured surface created by bombarding the surface with small media.

Similar to: RAL 9004, Pantone Black 6

Similar to: depends on material

Similar to: RAL 3031, Pantone 1805

Similar to: RAL 5015, Pantone 3015

Similar to: RAL 1037, Pantone 715

Similar to: RAL 1012, Pantone 612

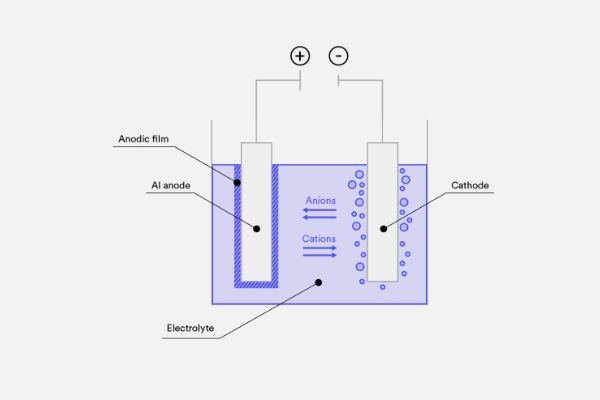

| Type | Impracticable situation | Features | Thickness(μm) | Application | Colors | PIC |

|---|---|---|---|---|---|---|

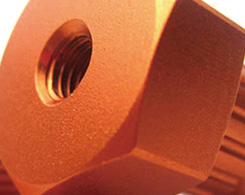

| Chromic acid (Type |) | a.Aluminum alloy parts with copper content > 5% b.Aluminum alloy parts with copper and silicon content > 7.5% | maintains the accuracy and surface roughness of original parts ,well bonding preformance | 3μm | a.1. Lap, riveted, welded or complex shaped parts b. Parts with high precision and low roughness | black,other color is imparctical |  |

| Sulfuric acid (Type II ) | Lap, spot weld or riveted part | the most common type of anodizing,can dye with a greater variety of colors | 0.5~20μm | The part that need brighten appearance or special color, as decoration or identification mark. | Black, Red, Blue, Green, Coyote Brown, Urban Grey, and Gold,allow for practically any hue |  |

| Hard Anodize (Type 1I) | Parts with high fatigue performance requirements | superior abrasion performance and electrical insulation,HV>420 | 30~120um | valves/hinges/cams/gear/insulation plates | black,other colors are less ornamental |  |

| Organic acid (Type IC) | uneven and amorphous black regions develop. | Anodizing can produce yellowish integral colours without dyes if it is carried out in weak acids with high voltages, high current densities, and strong refrigeration. | upto50um | Integral colour anodizing | pale yellow, gold, deep bronze, brown, grey, and black |  |

* Fixture Placement: During anodizing, components are suspended using a "jig" or "rack," which can result in marks where anodizing is not feasible. To prevent this, identify critical areas on your part where such marks are unacceptable.

* Electrical Insulation: Anodizing creates an insulating layer on your parts, impacting their conductivity. Factor in this change when designing components that require specific electrical properties.

* Masking Evaluation: Anodizing typically doesn't significantly alter the thickness of your part. So masking is usually unnecessary. However, if you wish to protect certain areas from anodization, clearly indicate these regions in your CAD file.

* Type III Anodizing: For Type III anodizing, which involves a thicker coating, consider masking or plugging threaded holes, reamed holes, and surfaces critical to your component's functionality. This precaution ensures that the added thickness doesn't interfere with the intended fit and function.

* Heat Dissipation: Anodizing affects thermal conductivity. Evaluate whether anodized surfaces might impact the component's heat dissipation properties.

Take advantage of our network and see what Xometry can do for you