Precision Machining

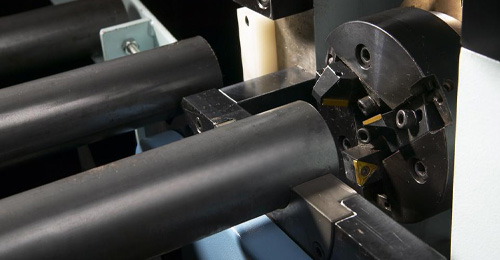

- CNC Machining Service

- CNC Milling

- CNC Turning

- Automatic Turning

- Machining Screw/Rivet

- Wire EDM Machining

- Casting & CNC

- Aluminum Profile & CNC

- Cold Heading & CNC

Various kinds of custom logo services for your needs.

*All uploads are secure and confidential

After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn more

It enhances the appearance and durability of edges by creating a beveled or chamfered edge on a surface. It is commonly used in various industries, such as manufacturing, architecture, and interior design, to create a clean and finish

learn more

Grinding is a process that smooths and polishes surfaces by removing small amounts of material through the use of abrasive stones or sandpaper. Grinding can be done by hand or with machines, and it is an essential tool for many trades and crafts.

learn more

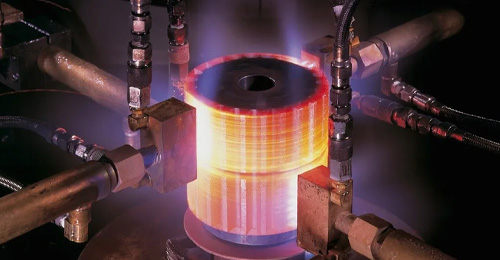

Heat treatment alters the physical and mechanical properties by heating them to a specific temperature and then cooling them at a controlled rate, improving the strength, hardness, and corrosion resistance of metal parts.

learn more

Welding is a process that joins two or more metal components by melting and fusing them together using heat and pressure. It requires skill and precision to ensure a strong and reliable joint.

learn more

Riveting is a process that joins two metal components securely by inserting a rivet through aligned holes and crimping its ends. It creates a strong and reliable joint. Riveting requires precision and skill to ensure a secure and reliable connection.

learn more

You are guaranteed to enjoy a 30% reduction in costs and competitive prices, which will assist you in procuring your materials and initiating your project.

In addition to our own factory, we have a network of suppliers to ensure a consistent supply of materials.

Each of our material bears certified material certification to guarantee excellent quality for your parts.

Our team of innovative engineers and skilled technicians is eager to assist you and provide recommendations for the most suitable materials for your needs.

Process: Ink is scraped through a screen plate onto the product surface. It is suitable for flat or simple curved surfaces.

Pros and Cons: Low cost and high adaptability, suitable for various materials and inks. However, it struggles with complex gradient colors and requires multiple prints for multi-color effects.

Process: A high-energy laser beam burns the material surface to create a permanent mark.

Pros and Cons: High precision, permanent durability, and non-contact processing. The drawback is that it typically produces single-color marks (e.g., the material’s original color) and requires high initial equipment investment.

Process: Material is removed chemically or physically to create concave-convex patterns.

Pros and Cons: Results in long-lasting, detailed patterns. However, it involves chemicals that may environmental concerns and is not suitable for all materials

Process: The logo is formed directly during product molding, creating raised or recessed effects.

Pros and Cons: High efficiency and low cost once the mold is made. The disadvantages include inflexibility for modifications and high precision requirements for the mold.