Precision Machining

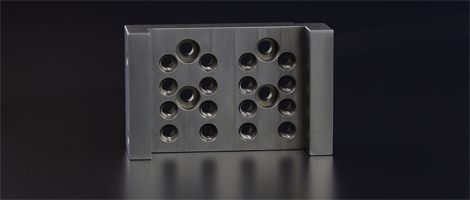

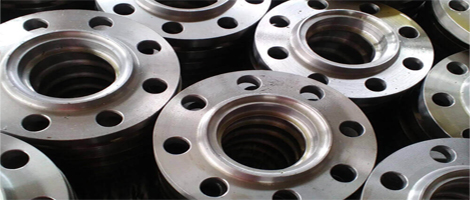

- CNC Machining Service

- CNC Milling

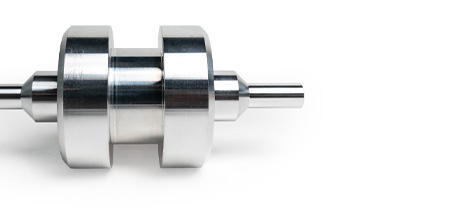

- CNC Turning

- Automatic Turning

- Machining Screw/Rivet

- Wire EDM Machining

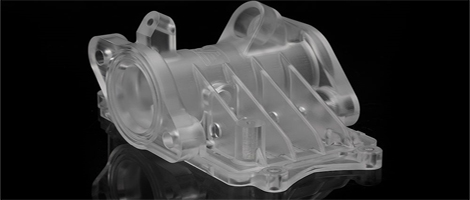

- Casting & CNC

- Aluminum Profile & CNC

- Cold Heading & CNC

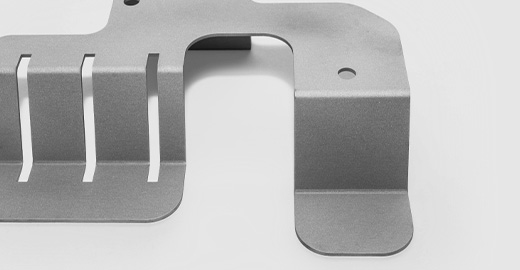

We deliver high-precision, complex metal stamping solutions tailored for demanding industries, utilizing advanced presses and custom-designed dies to rapidly transform sheet metal into high-volume components with exceptional accuracy, consistent quality, and cost-effective efficiency.

Certificates: ISO 9001:2015 | CE | ROHS

CNC turned prototypes and production parts in days.Advanced machines include Swiss lathes and multi-axis mill turns

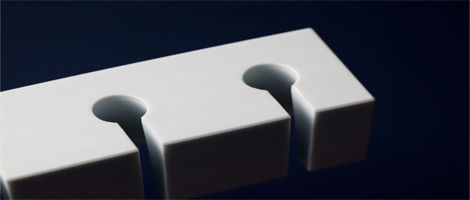

CNC milled prototypes and production parts in days including standard 3-axis mills.indexed 3+2-axis mils & fully-continuous5-axis mills.

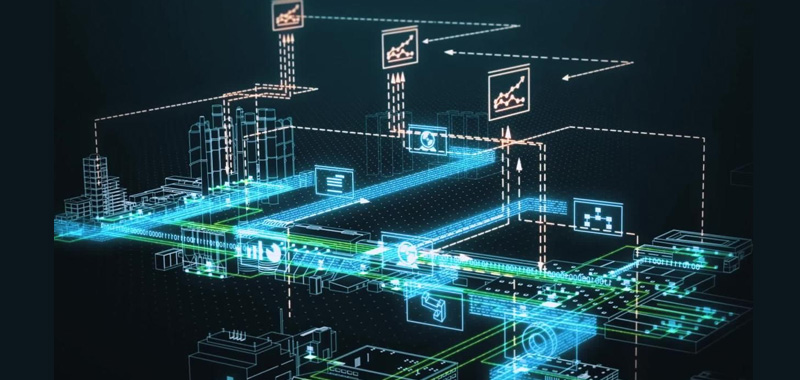

LML takes great pride in its extensive and diverse manufacturer supply network, encompassing a range of specialized factories.With a strategic investment approach, LML has forged partnerships with various manufacturing facilities, including CNC machining, sheet metal fabrication, die casting, and silver contact factories.This robust network of factories allows LML to provide comprehensive solutions for a wide array of manufacturing needs.Over 100+factories; Coorperate with over 50 countries and 2000 customers.

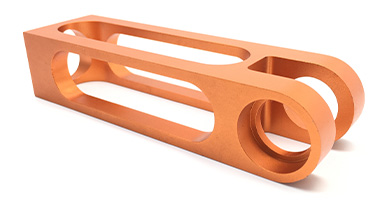

Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. Can be anodized.

Aluminum 2014/5052/60606063

Aluminum 6082/7050/2017A

Aluminum 2024-T3/2024-T351

Aluminum 5083-H 111

6061-T6/6061-T651/6082-T651

7075-T6/7075/T651/7075/T7351/A380/MIC6

Learn more

Brass demonstrates excellent electrical conductivity and good machinability. Known for its low friction properties and gold-like appearance.

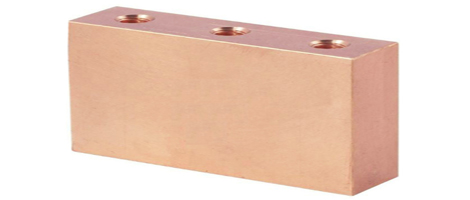

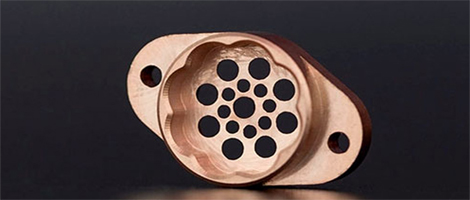

Copper have good strength, hardness, superior thermal and heat conductivity, and corrosion resistance. Consequently, it is a popular material valued for its functional and aesthetic functions.

Bronze is great for applications such as bearings as well as marine applications on pumps and fittings where corrosion resistance against seawater is required.It is best used on low-stress components made with CNC machining

tainless steel is a ubiquitous metal critical to a myriad of industries from medical to power generation. Its value lies in its strength, heat resistance, and exceptional corrosion resistance.

Carbon steel has high tensile strength Cost-effective, Easy to weld, Easy to machine

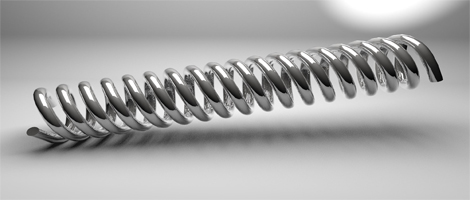

Spring steel have high yield strength and have the ability to withstand stress without permanent deformation.Spring steels are high in carbon along with traces of other elements.

High hardness and stiffness, abrasion resistant. Tool steels are metal alloys with exceptionally high hardness, stiffness and abrasion resistance. Suitable for manufacturing industrial tools.

Titanium have excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

High-strength and corrosion-resistant nickel alloy. Inconel is a high-strength, corrosion-resistant nickel alloy. Ideal for aerospace applications.

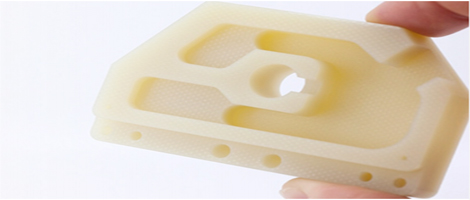

ABS is a commonly used thermoplastic polymer with excellent impact, temperature and chemical resistance. It is also easy to machine and process and has a smooth surface finish.

Flame retardant glass fiber epoxy laminate. FR4 is a class of glass fiber epoxy laminate that is flame retardant, with similar properties to G-10.

Nylon is a widely-used engineering plastic with good toughness, abrasion resistance, and hardness characteristics. Nylon 66 properties make it ideal for load-bearing mechanical components.

Delrin have good mechanical properties notable resistance. In addition to its exceptional mechanical properties, CNC machined acetal offers superior dimensional stability that makes it ideal for high-precision parts.

POM (Polyoxymethylene) is an engineering thermoplastic material that demonstrates excellent dimensional stability, stiffness and impact and temperature resistance.

Acrylic is a transparent thermoplastic. One of the most widely used plastics in the world, PMMA demonstrates good chemical stability, mechanical properties and weather resistance. The material is also easy to process and to dye.

Garolite G-10 is a composite material with a low coefficient of thermal expansion. Additionally, it does not absorb water and is an excellent insulator, which makes it really useful for electronics applications.

High strength-to-weight ratio. Thermo-oxidative stability. Excellent mechanical properties. High temperatures resistance and more…

Polypropylene (PP) is an inexpensive thermoplastic with variable impact resistance depending on the grade. PP is wear-resistant, flexible and can have high elongation, while it also has high chemical resistance.

Polyethylene (PE) is a thermoplastic available as high-density polyethylene or low-density polyethylene. High-density polyethylene, PE also offers good electrical insulation, impact resistance and temperature resistance.

| Limits for nominal size | Plastics (ISO 2768- m) | Metals (ISO 2768- f) |

|---|---|---|

| 0.5mm* to 3mm | +0.1mm | +0.05mm |

| Over 3mm to 6mm | +0.1mm | +0.05mm |

| Over 6mm to 30mm | +0.2mm | +0.1mm |

| Over 30mm to 120mm | +0.3mm | +015mm |

| Over 120mm to 400mm | +0.5mm | +0.2mm |

| Over 400mm to 1000mm | +0.8mm | +0.3mm |

| Over 1000mm to 2000mm | +1.2mm | +0.5mm |

| Over 2000mm to 4000mm | +2mm | +0.5mm |

| Feature | Design Guideline | Technical Rationale |

|---|---|---|

| Minimum Hole Size | ≥1.2× material thickness (e.g., 1.2mm hole for 1mm steel) | Prevents punch breakage and excessive die wear |

| Edge Margin | ≥2× thickness from hole to edge (≥3× for notches) | Avoids material deformation during blanking |

| Bend Relief | Width = thickness, Length = 1.5× thickness | Prevents tearing at bend intersections |

| Embossing Height | ≤30% of material thickness | Maintains structural integrity |

| Tolerances | ±0.1mm (progressive die), ±0.25mm (compound die) | Tooling precision limitations |

| Radius Requirements | Punch radius ≥0.5× thickness, Die radius ≥3× thickness | Controls material flow and springback |

| Material Selection | Best for: Cold rolled steel (CRS), Aluminum 5052, Brass 260 | Optimal formability-to-strength ratio |

| • Standardize hole sizes | • Minimize multi-axis bends |

| • Avoid sharp corners (≥0.3mm radius) | • Use common stock thicknesses |

General and tight tolerances

Learn More

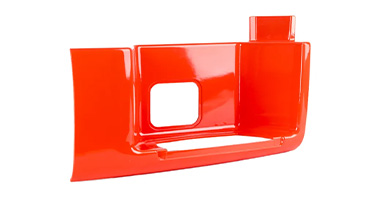

Finishes and visual inspection

Learn More

Edge breaking, deburring and cleaning

Learn More

Sampling rules, AQL and defects classification

Learn More

Applicable to different material hardness

Learn More

A unit of length in different countries

Learn More24-hours sales' service online Communicate now!

Configure your part specifications of drawing, material, tolerance, finish and quantity.

we provide you with samples based on drawings. You can examine and confirm that the samples meet your expectations. If not, reproduce the sample!

Ensure adherence to the confirmed specifications when mass production.

100% quality control assurance.

Photos and videos quality inspection data for you!

24-hours sales'service online Communicate now!

Custom Packing with wooden, carton, plastic materials for you to choose.

Delivery products to your specified location by express, sea, air...

Don't Worry!

24-hours sales' service online

Communicate now!

Conmmunicate your requirements of drawing, material, tolerance, finish and quantity.

Engineer will design drawing for your reference depending on your delivered samples or your needs! And we confirm the final drawing before production.

we provide you with samples based on drawings. You can examine and confirm that the samples meet your expectations. If not, reproduce the sample!

Ensure adherence to the confirmed specifications when mass production.

Photos and videos quality inspection data for you!

Custom Packing with wooden, carton, plastic materials for you to choose.

Delivery products to your specified location by express, sea, air...

LML will provide you with a fast, free quotation and drawing service. Your platform for efficient and reliable procurement of high-quality complex metal and plastic parts.

To start sourcing CNC machined partsfrom LML, simply contact us today and our engineers will quickly understand your needs, then draw drawings and produce samples for your reference. If you already have a perfect drawing, our engineers will produce it for you after confirming the drawing, and provide visual quality control services and order tracking.

CNC Machining includes CNC turning and CNC milling, which is widely used in automotive, communication, medical, clocks and watches, cell phones, computers and other industries. Machining of mechanical parts generally refers to the sum of the machining process of parts and the assembly process of machines, and other processes are called auxiliary processes, such as transportation, storage, power supply, equipment maintenance, etc.

CNC machines manufacture robust parts with tight tolerances and a range of impressive material properties (mechanical and chemical). Our custom CNC machining service is ideal for one-off jobs and low-to-medium volume production, thanks to automation and high repeatability.

LML takes pride in its extensive network of cooperative investment factories. These partnerships encompass various sectors, such as CNC processing, sheet metal processing, die-casting, screws, silver contacts, and more. With these collaborations, we have access to abundant factory resources, allowing us to provide a comprehensive supply chain solution to our customers.

Our aim is to offer a convenient and hassle-free experience by serving as a one-stop destination for all your manufacturing needs. Whether you require CNC machining, sheet metal fabrication, or specialized components, LML ensures seamless coordination and efficient delivery, guaranteeing exceptional quality and customer satisfaction.

Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications.

Read Article

What is CNC machining and how does it work? Learn the basic principles and fundamental mechanics, as well as the key benefits and limitations, of this subtractive manufacturing process

Read Article

In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts.

Read Article

Make the most of CNC machining by optimizing your design and making the right material choices. Read these 14 design tips to help you reduce CNC-machining costs and create the perfect parts for your project.

Read Article

Laser cutting, bending, welding, post-processing

CNC production parts in few days

Indexed 3+2-axis mils & fully-continuous5-axis mills.

By leveraging the strengths of CNC machining and casting, LML optimizes production efficiency while maintaining exceptional quality standards.

On December 12 , 2019,LML welcomed three customers again.

Read more

On December 12 , 2019,LML welcomed three customers again.

Read more

On December 12 , 2019,LML welcomed three customers again.

Read more