Which Occasion Is Countersunk Head Rivet Suitable?

Countersunk head rivet is a part that is rivetedby the way of self-deformed or interconnected joints. Countersunk head rivetsare widely used in automobiles, vehicles, mechanical and electrical products,building decoration and household appliances. It is suitable for the occasionwhich the screws screwing in, the strength requirements are not high and the threaddiameter is less than 10mm. When it rivets, all or part of head will sink intothe connection. This riveting structure is mainly used for the occasion thatthe surface of connection is smooth, such as the instrument surface.

A “countersunk rivet” typically has a flathead and can have a tubular or solid shank rivet. Among the raw materials usedto produce these rivets is steel, stainless steel, aluminum, brass, and copper.Rivet plating and coating options are selected by end user dependent on theapplication.

Countersunk head rivets are used to joinwork-piece materials together where the head of the assembled rivet will beflush with the top of the work piece. Countersunk head rivets are also used tohold friction materials to brake shoes. Riveted work-pieces are most oftenjoined together by impacting or compressing the end of the rivet with acrimping die (rivet anvil).

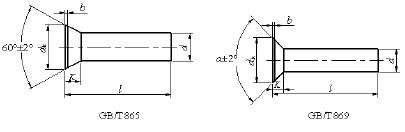

Countersunk head rivet angles should matchclosely the angle of the work piece hole so that the maximum amount of rivethead remains in contact with the work piece when the rivet is assembled. Thelength of the most countersunk head rivets are measured from the top of thehead to the extreme end of the rivet shank. The tightness of the clinched jointis determined by the amount of force applied to the clinched end of the rivetand can easily be adjusted.

According to GB / T3098.18-2004, the mechanicalperformance test of countersunk head rivets includes shear, resistance, nailholding capacity, mandrel disassembly force (before installation) and nail corebroken totally 5 items. By the way, the riveting capability and shear strengthalso can be tested in accordance with the requirement of use

Cracks which will affect usage are notallowed in the surface of countersunk head rivet. Small metal bumps are alsonot allowed at the top of the nail. In addition, round blunt, flash, bumps,streaks are also not allowed.